Riveting the trailing edge 3h

3h

June 17, 2022

Today I riveted the trailing edge of the rudder.

After giving a day and a half for the tank sealant to dry, I removed the aluminum angle from the trailing edge.

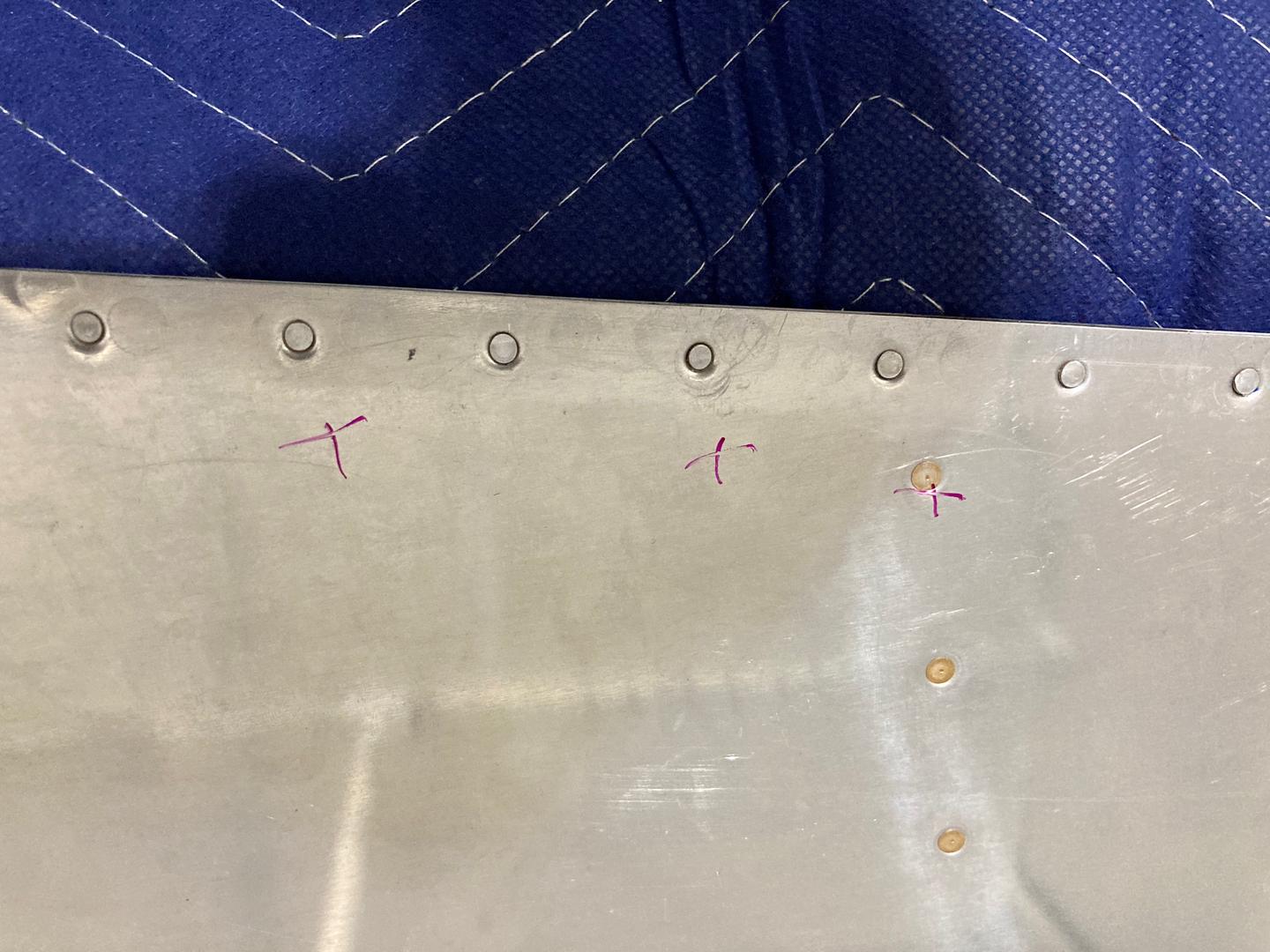

The edge looked good, so I started riveting it. The process was to partially set every 8th rivet first, then every 4th, then every 2nd, and, finally, set the remaining rivets.

I used the manual squeezer and flat dies to partially squeeze the rivets square to the skin on the manufactured head skin side.

You can see that maybe I used a bit too little of the tank sealant -- the skins are not tight to the angle, unfortunately. Also, I did not use the roller tool on the edge (I was afraid that skins will get stretched and will be wavy), which could have helped, too.

Does not look too bad, and it is mostly on the top part only. The bottom of the edge looks better.

Then I used the trailing edge dies to squeeze all the rivets. I used the same pattern (every 8th, every 4th, etc).

The final result is still relatively straight. I've got some amount of deflection after the riveting, but it is less than 1/32" of an inch (or 0.031").

The shop heads look okay.

Finally, I spent some time deburring the skins for the elevators. I decided to try using just the sandpaper (previously, I was using a die grinder with the roloc wheel). It worked out okay, but it is slower. Less noise, though, and less risk of bending the skin if it catches the wheel.